BDR Stainless is a multi-disciplinary engineering company committed to delivering high-quality solutions across a range of industries. We specialise in the full lifecycle of engineering services, including:

- Fabrication

- Maintenance

- Mechanical Installation

Our well-equipped workshop enables us to efficiently support projects of varying scale and complexity. Backed by experienced Project Managers, we ensure every project is executed with precision, professionalism, and a strong focus on meeting client expectations.

Certified Integrated Management System

BDR Stainless operates under a Third-Party Certified Integrated Management System, which underscores our commitment to quality, safety, and environmental responsibility. Our certifications include:

- ISO 9001 – Quality Management Systems

- ISO 45001 – Occupational Health and Safety Management

- ISO 14001 – Environmental Management Systems

These certifications affirm our capability to consistently deliver safe, sustainable, and high-quality engineering services. “If it can’t be done safely, it won’t be done”.

Engineering/Design

At BDR Stainless, our Engineering services are delivered through a dedicated Project Management Office (PMO), supporting our operations across a broad spectrum of industries, including:

- Water/Wastewater

- Oil & Gas

- Industrial

- Infrastructure

- Defence

We are committed to excellence, executing all engineering work in strict accordance with the ISO 9001 Quality Management System and other relevant international standards.

Our Capabilities Include:

- Shop Detailing – Fabrication-ready drawings to ensure accuracy in manufacturing.

- Mechanical Engineering – Design and analysis of mechanical systems and components.

- Process Engineering – Optimisation and design of process systems for operational efficiency.

- HAZOP – Hazard and Operability studies to identify and mitigate design risks.

- Structural Engineering – Analysis and design of structural elements across various sectors.

- RPEQ Certification – Registered Professional Engineer of Queensland sign-off for regulatory compliance.

- Feasibility Studies – Technical and financial assessments to guide decision-making.

- Scope Development – Clear and actionable project scope documentation.

- Reverse Engineering – Analysis and recreation of existing components and systems.

- Engineering Management – Oversight and coordination of multi-disciplinary engineering efforts.

- Project Management – End-to-end leadership and control of project timelines, budgets, and quality.

Fabrication / Workshop

At BDR Stainless, we specialise in brownfield upgrades and modifications for existing sites and operational environments across diverse industries, including:

- Water/Wastewater

- Oil & Gas

- Industrial

- Infrastructure

- Defence

Our approach leverages deep expertise in fabrication, and asset maintenance to develop asset lifecycle strategies. These strategies optimise capital works programs and extend the functional life of critical assets—delivering long-term value for our clients.

Workshop Capabilities & Services

Our fully equipped manufacturing facility in Tingalpa, Brisbane, supports a wide range of fabrication services, with a strong emphasis on precision, quality, and safety. Key offerings include:

- Structural Steel, Access Systems & General Fabrication

- Advanced Equipment & Processes:

- Brake Press

- Guillotine

- Rollers

- Orbital and Specialised Welding Machines

- Pressure Equipment:

- Pressure Piping & Vessels

- Tanks, Chutes, Hoppers

- Metalworking & Processing:

- Machining

- Folding

- Cutting

- Comprehensive QA/QC/OH&S Compliance – Ensuring all projects are executed to the highest quality and safety standards.

- Multi-Material Expertise:

- Carbon Steel

- Stainless Steel/Duplex

- Aluminium

- Other Alloys

- End-to-End Project Management – From concept through to delivery and commissioning.

Installation On-site

BDR Stainless delivers trusted on-site installation and facility maintenance services to clients in the water/wastewater, industrial, oil & gas, infrastructure, and defence sectors throughout Australia.

Our teams consist of qualified engineers, QAQC Inspector, skilled tradespeople, and experienced site supervisors, all dedicated to upholding the highest standards of safety, quality, and compliance.

On-Site Capabilities Include:

- On-Site Fabrication & Installation – Precision fabrication and assembly at your facility.

- A highly skilled mechanical installation team – Delivering complex and large-scale installations and maintenance services.

- Plant Shutdown Specialists – Time-critical works delivered safely and efficiently during shutdown windows.

- Relocation & Decommissioning – Secure dismantling, relocation, and recommissioning of assets.

- Fully Mobile Work Teams – Rapid mobilisation across sites for responsive service.

- On-Site Measure & Drafting – Accurate field data capture and real-time drawing updates.

- Multi-Material Expertise:

- Carbon Steel

- Stainless Steel

- Aluminium

- Other Alloys

- Full QA/QC/OH&S Compliance – Adherence to rigorous safety and quality frameworks.

- End-to-End Project Management – Seamless execution from planning to commissioning.

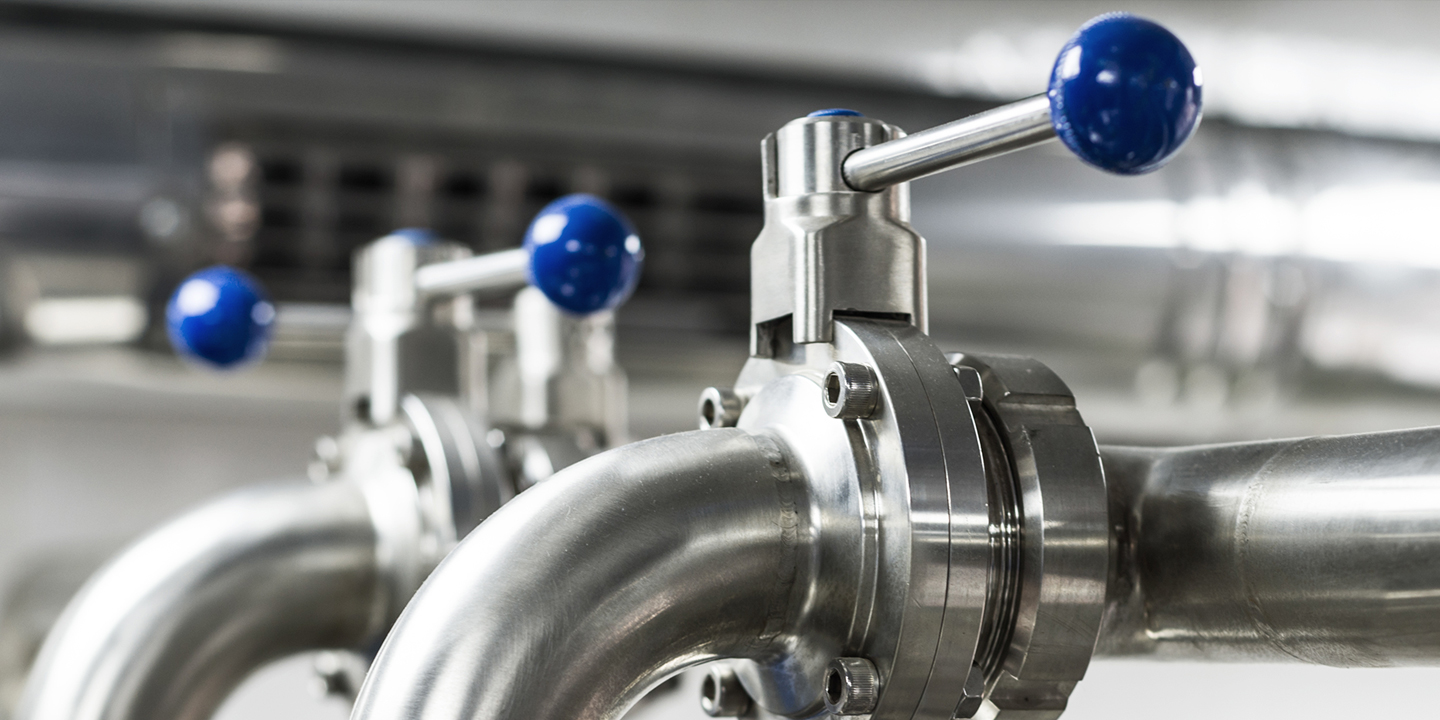

Maintenance Services

At BDR Stainless, our Maintenance Services Team provides comprehensive mechanical, fabrication, and infrastructure support across multiple industries, including:

- Water/Wastewater

- Oil & Gas

- Industrial

- Infrastructure

- Defence

Our services range from corrective and preventative maintenance to major shutdowns and complex fabrication/installation works. Operations are supported by our well-equipped workshop facility in Tingalpa, Brisbane, enabling efficient planning, execution, and rapid mobilisation.

Maintenance Capabilities Include:

- Emergency Services & Repairs – Fast-response teams to restore functionality with minimal disruption.

- Mechanical Breakdowns – Troubleshooting and repair of critical mechanical systems.

- Skilled Trades – for maintenance, installation, and plant upgrades.

- Fabrication & Scheduled Maintenance

- Repairs to Valves & Pipes – Swift and effective piping maintenance services.

- Full QA/QC/OH&S Process – Rigorous quality and safety protocols at every stage.

- Project Management – Planning, execution, and reporting of all maintenance tasks.

Core Capabilities & Principal Activities

BDR Stainless delivers a broad range of mechanical, engineering, and maintenance services, supported by a cohesive team of professionals with extensive experience and a strong history of collaboration. Our team’s proven track record in successfully delivering complex and high-value projects sets us apart in the market.

We serve a diverse client base across Australia including some of the country’s leading names in resources, infrastructure, industrial, and government sectors.

Our Principal Activities Include:

- Project Management

Full-spectrum project control from planning through execution and handover, delivered by experienced managers. - Facilities Management & Maintenance

Lifecycle asset management and maintenance programs, tailored to client needs and compliance requirements. - Industrial Upgrades & Extensions

Complex brownfield enhancements and plant expansions conducted safely in live operating environments. - Fabrication

High-quality metalwork across stainless steel, carbon, aluminium, and other specialty materials, backed by a well-equipped Brisbane workshop. - Overhauls & Plant Equipment Repair

Mechanical overhauls, refurbishment, and repair of industrial machinery to maximise uptime and asset longevity. - Water Treatment Facilities

Engineering and installation of infrastructure supporting potable and process water systems. - Process Systems

Design and integration of efficient and compliant process equipment tailored to unique operational requirements. - Specialised Engineered Equipment

Bespoke design and fabrication of purpose-built equipment to support niche industrial applications.